Morton Machine Rebuild

Filed Under: #lathe , #machining , #morton

The Morton is back!

We recently made the decision to have our Morton Machine refurbished. Breathing new life into the Morton will improve our efficiency when working on the biggest of our customer’s machines. After sometime, Marion Machine is pleased to announce that the Morton Machine is back and running like new!

Some of the important repairs were:

-Replacing broken and bent clamps

-Repairing the gibs by straightening the runs and scrapping the surfaces

-Repairing the lubrication lines for proper oil application

-Replaced all wipers for axis protection

The Morton gives us the capability to line bore parts, mill surfaces, and drill holes in large fabrications and castings, while holding close tolerances.

Do you have equipment that needs machined? Send us a request at https://marionmachinellc.com/need-a-repair/.

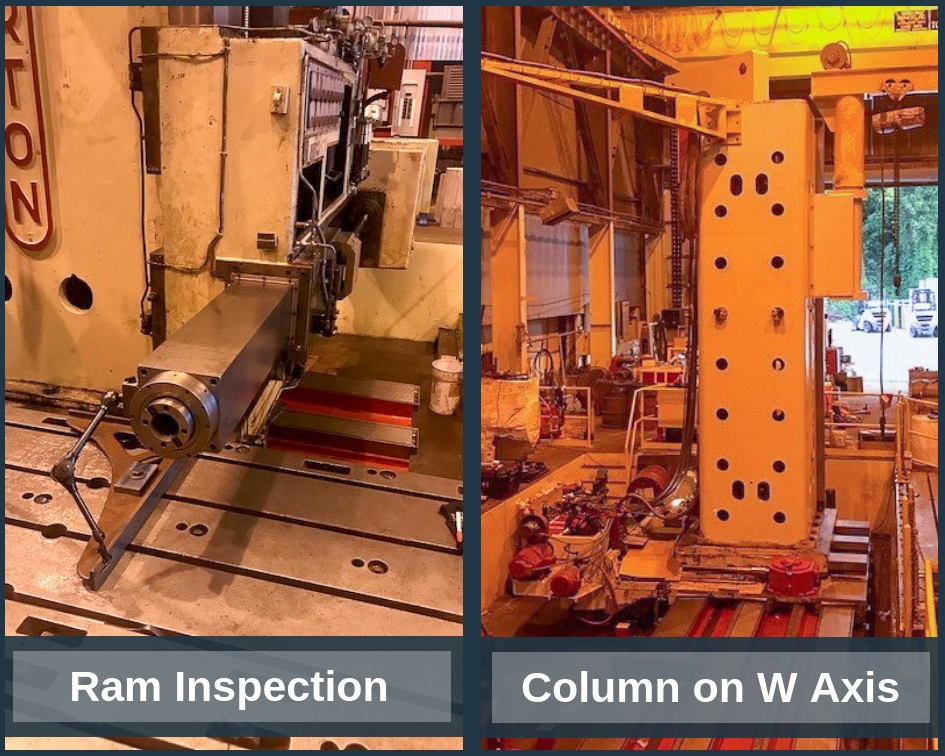

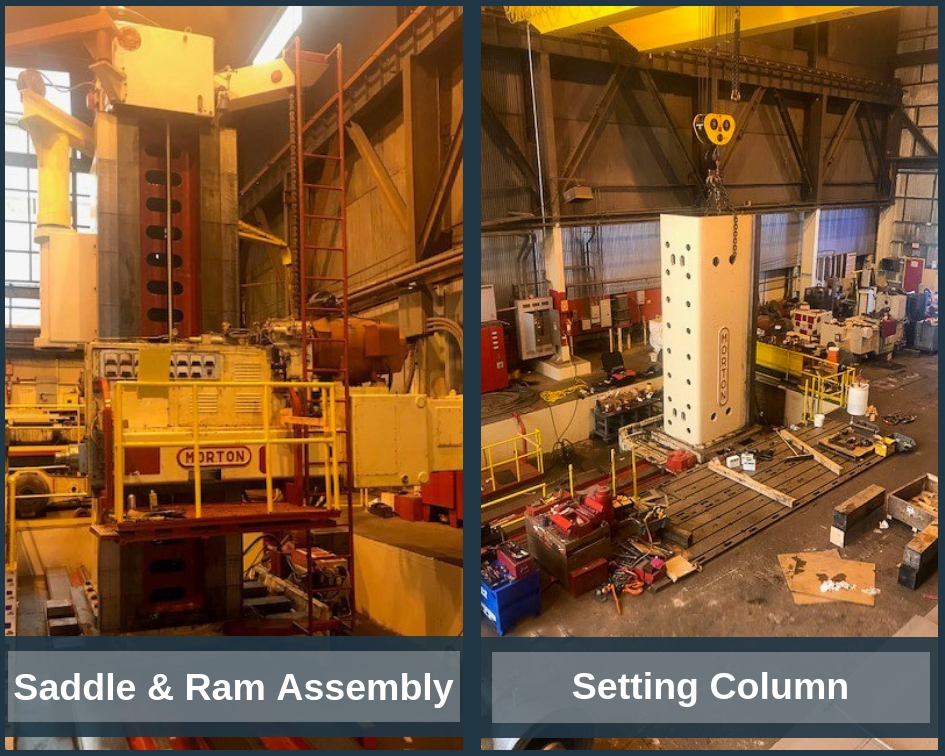

Check out pictures of the reassembly below!

Christopher Joyce Vulcan Materials of Winston-Salem, NC

Our Metso HP 800 Mainframe had a loose shaft and we re-fit the shaft back to OEM specs with a 2-week-turnaround to get a 3.5-million-ton-plant back up and running.