Machining, From Back in the Day, to Today

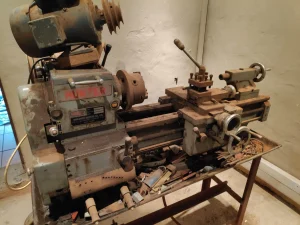

Machining a process that involves raw materials being cut into a certain shape through the removal of certain materials. Basically wood, ceramic, metal, or other composites are shaped into a final product. Most people do not realize the machining process is key to the mobilization and growth of civilization as we know it today. The original tools used for machining date back to 1200 B.C. and were used in Ancient Egypt. Machining has been an integral part of civilization since. The average person does not know much if anything about machining and its importance to manufacturing. It is said that the first machine tool to be manufactured was a boring machine that fed on the energy that was produced by a hydraulic drive, created by John Wilkinson in 1774. Later, around 1800, Henry Maudsley fabricated the first screw-cutting lathe in England, which would give way to the first planing machine. In 1842 the first automatic lathe was built, in 1846 a very precise drilling machine was created. Then in 1860 the first cylindrical grinding machine was up and running, until the year 1861 when the first universal milling machine was manufactured.

These machines continue to advance into larger machines that do more specific tasks. Marion Machine specializes in machining very large equipment, and Joe McNeill gave us a little Marion history. He said, “Marion Machine learned its processes from naval shipyards and developed our own techniques from there. We combined the old processes with the new to make something awesome. In the beginning we worked with railroad materials and other large projects that launched our region into the booming county it is today.”

Now that you know the history, the big question is, when is it time to repair your machines? The answer is, if you hear any odd noises or visually see that the machine is working differently you should contact a machine repair shop such as Marion Machine, as soon as possible for an inspection. You should also perform preventative maintenance as scheduled for that piece of machinery. Repairing your equipment can get a little pricey but it is important to keep in mind that the new price of item has a huge bearing on the cost of repairs. For Help with your repairs call Marion Machine. https://marionmachinellc.com/

Christopher Joyce Vulcan Materials of Winston-Salem, NC

Our Metso HP 800 Mainframe had a loose shaft and we re-fit the shaft back to OEM specs with a 2-week-turnaround to get a 3.5-million-ton-plant back up and running.