Expert Thread Repairs for Rock Crushers | Marion Machine

At Marion Machine, we specialize in providing industry-leading thread repair services for rock crushers. With decades of experience, our experts are equipped to handle the most challenging thread repairs, ensuring your equipment operates at peak efficiency.

High-Quality Thread Repair for Cone Crushers

Precision is key when it comes to rock crusher performance, and high-quality bowl and adjustment ring threads are essential for producing the precise end product you need. Our thread repair services primarily focus on two critical components of cone crushers: adjustment rings and bowls. This is especially important for crushers with hydraulic crusher clearing and tramp release systems, which tend to increase thread stress during operation.

Why Thread Repairs Are Critical

Thread repairs are often necessary due to galling, a common issue where metal parts fuse together under pressure. Galling can severely impact the ability to adjust closed side settings and open side settings on your crusher, resulting in decreased performance. Robust threads are crucial for maintaining fine adjustments, helping your equipment consistently produce a high-quality product.

Marion Machine’s Advanced Thread Repair Process

At Marion Machine, our thread repair process ensures that repaired threads have the optimal metallurgical profile, balancing both hardness and elongation factors to withstand the rigors of rock crushing applications. As a Metso Authorized Repair Facility, we have the unique ability to restore machine threads and other parts back to their precise factory specifications, ensuring maximum performance and longevity.

Need Thread Repair Services for Your Equipment?

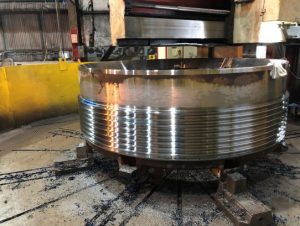

Don’t let damaged threads impact your production. Let the experts at Marion Machine handle your thread repairs and help you maximize your crushing potential. Contact us today at 1-800-627-1639 or visit our capabilities page to see how we can restore your worn or damaged equipment. Be sure to check out the pictures of our work below for a glimpse of our high-quality results!

Christopher Joyce Vulcan Materials of Winston-Salem, NC

Our Metso HP 800 Mainframe had a loose shaft and we re-fit the shaft back to OEM specs with a 2-week-turnaround to get a 3.5-million-ton-plant back up and running.