Employee Spotlight – Keith Cox

Marion Machine is proud to introduce you to one of our most experienced and devoted employees, Keith Cox.

Keith began working for Marion Machine 30 years ago, in 1991! He never fails to be a role model for new employees, and he is fully invested in the younger generation, taking many new employees under his wing.

Keith began working for Marion Machine 30 years ago, in 1991! He never fails to be a role model for new employees, and he is fully invested in the younger generation, taking many new employees under his wing.

Keith treats everyone with respect and always finds a way to turn a mistake into a learning experience.

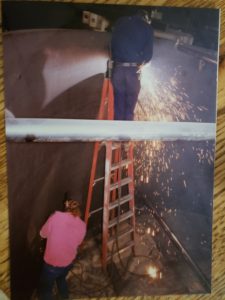

Safety in the workplace is a priority for Keith and he serves as a role model to encourage others to follow his example. Since working at Marion Machine, Keith has worked in our welding and assembly departments, and he also pours babbitt bearings for our customers. He is also a master blacksmith, fabricator, and welder. We are very proud to have Keith on our team and look forward to many more years of service with him!

We sat down with Keith to ask him a few questions.

Q: What is your favorite memory at Marion Machine?

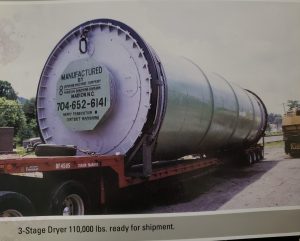

A: “I guess when we built that big dryer in building 2. It was a 105,000-pound grain dryer and we had to lay railroad track in the floor of the building to move it around. We built carts and put each end of the dryer on a cart to move it. CF Reese used 2 cranes to move the dryer.”

Q: What do you like most about your job?

A: “I am just interested in working on the large parts”

Q: What advice would you give to others looking to work for Marion Machine?

A: “Do a good job the first time.”

Q: What do you enjoy doing in your spare time?

A: “Fishing, hunting, black smith, and riding motorcycles.”

The first picture above is a picture of Keith today. The others are pictures from his earlier days at Marion Machine, as well as pictures of the large part that Keith spoke of during our interview.

Christopher Joyce Vulcan Materials of Winston-Salem, NC

Our Metso HP 800 Mainframe had a loose shaft and we re-fit the shaft back to OEM specs with a 2-week-turnaround to get a 3.5-million-ton-plant back up and running.